Swift replacement of an established industry-standard overspeed protection system with Istec SpeedSys 300 and proactive support from Konrad Weinmann

Challenge

Dillinger Hütte, Europe’s largest heavy plate steel plant, required an urgent replacement of its Legacy overspeed detection system. The existing system was complex, included additional external trip signals, and had been overlooked during a previous control system retrofit. By June, the team faced a tight deadline: commission a reliable overspeed protection system within just a few months.

The challenge was twofold:

- The system included external built-in trip signals and complex functionalities, which initially made the replacement appear more complicated.

- Dillinger’s team needed to gain confidence in operating a new overspeed detection system after years of using another system, while minimizing risk and downtime during and after the transition.

Additionally, Dillinger required fast delivery, clear configuration support, and assurance that their team could depend on Istec for expertise and responsibility in implementation.

Solution

Initially, Dillinger aimed for a one-to-one replacement of the system. However, after a thorough system survey and I/O analysis, the teams jointly concluded that several functionalities were redundant. This led to a simplified “back to basics” solution, focusing purely on overspeed protection and essential functions.

Together with distribution partner Konrad Weinmann, Istec proposed the SpeedSys 300 Overspeed Detection System as the optimal solution for Dillinger’s requirements.

Leveraging Weinmann’s deep technical knowledge of the Istec portfolio, the team advised on the most effective replacement strategy, ensuring a smooth transition and alignment with the existing setup.

This approach:

- Reduced system complexity

- Lowered installation time and cost

- Increased user confidence and ownership

Key steps in the process:

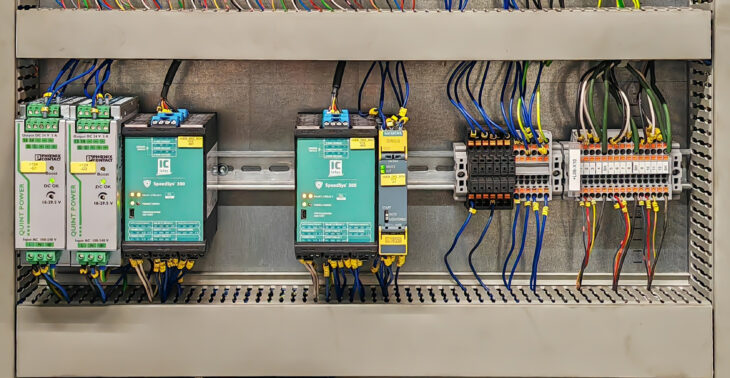

- Simplification: The system was streamlined to focus solely on overspeed protection. Redundant relay functions were removed based on a detailed system analysis. The SpeedSys modules were mounted directly onto the existing DIN-rail, enabling a fast and clean installation.

- Flexibility during installation: During commissioning, one of the sensors was found to be malfunctioning. Originally, the system was configured with a 2oo3 voting structure. However, the setup was swiftly adapted to a 2oo2 configuration on-site. This change was implemented without delay, demonstrating the adaptability of SpeedSys to practical conditions and reinforcing its suitability for dynamic environments.

- Engineering: Standard drawing packages and configuration files were prepared to enable straightforward integration. Dillinger’s engineering team could carry out the installation independently, maintaining full ownership of the overspeed protection scope.

- Installation: By the end of August, all wiring and assembly were completed, ready for commissioning. What set this project apart was the pace and efficiency: delivery was fast, and technical details were clarified, discussed, and adapted to the new situation without delay. This resulted in a situation where the groundwork for commissioning could have been finalized within one week.

- Remote commissioning: Instead of lengthy on-site visits, Istec provided step-by-step remote programming support. Within a few hours, Dillinger, Weinmann, and Istec successfully configured and tested the system together.

- Collaboration: Konrad Weinmann played a key role as distributor and technical partner, bridging customer needs with Istec’s solution. Their expertise and customer-centric approach ensured timely and effective project execution.

- Support: Both Istec and Weinmann remained available for questions and support. Istec’s service team was on standby for on-site assistance if needed. An additional module was supplied to minimize downtime risk in case of failure.

Impact

The new SpeedSys installation provided Dillinger with a reliable, accessible, and easy-to-maintain overspeed protection system in just 3 months. Free of unnecessary complexity compared to the previous system.

As a boutique style company, Istec, as opposed to other players in the market, was able to have short lines of communication, offer quick and local partner support, keep shipping times short and offer intuitive and accessible systems.

Key results:

- Efficiency: Remote commissioning was completed in just a few hours, avoiding a full-day on-site effort and reducing costs.

- Simplicity: The “back to basics” approach eliminated redundant features, focusing only on what Dillinger truly needed. This reduced complexity, cost, and the need for extensive training.

- Availability: SpeedSys modules were quickly supplied, and spare units could be configured within minutes, ensuring minimal downtime risk.

- Customer satisfaction: Dillinger’s engineering team appreciated Istec’s clarity, responsiveness, and ownership of the overspeed protection scope.

- Partnership success: The collaboration with Konrad Weinmann highlighted the strength of Istec’s distributor model, combining commercial outreach with deep technical expertise.

Conclusion

This project marked a successful legacy system-to-SpeedSys replacement, setting a benchmark for future retrofit projects. It demonstrates what is possible in a short timeframe when client, distributor, and Istec are aligned, take ownership, and share responsibility. Clear in-house knowledge from Dillinger, expert advice from Weinmann, and effective technical support from Istec enabled in a smooth and swift transition to a modern overspeed protection system. For Dillinger Hütte, the result is a lean, robust system that maximizes safety, uptime, and ease of use, in just three months.

Looking to replace an obsolete overspeed protection system? Contact Istec or your local distributor to explore how SpeedSys can simplify your retrofit project and enhance machine safety. Quickly, reliably, and without unnecessary