To measure the rotational speed of a shaft, it is necessary to have the right target for the contactless-sensing speed sensors to be able to generate an accurate signal. In many cases an existing gear can be used for this, but when this is not present or able to be used there are various methods to still be able to generate speed signals. Four different methods are described.

Pole wheel

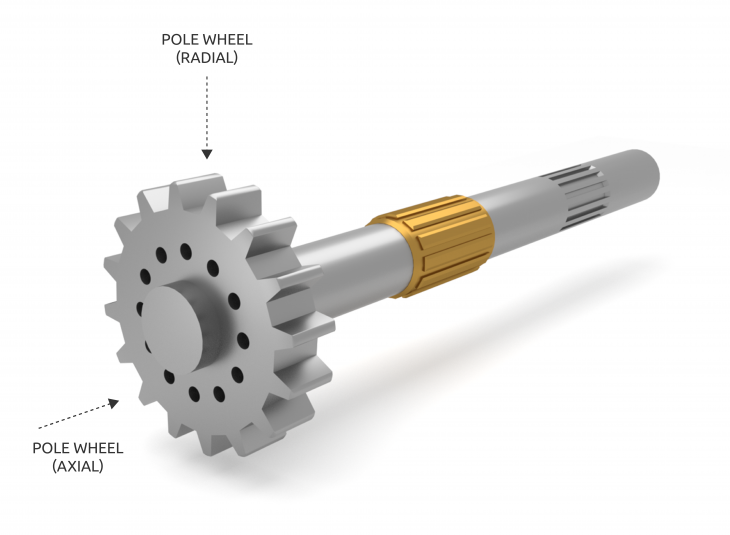

A pole wheel can be used to perform speed measurements and supports both radial and axial measurements. For radial measurements the air gaps between the gear tooth are used to generate a speed signal.

For axial measurements the air gaps in the holes/notches of the pole wheel are used to generate a speed signal. Both the speed signals from axial and radial measurements are then used to calculate the rotational speed of the speed wheel, which is equivalent to the rotational speed of the shaft.

The images below are solely for illustration purposes. It shows the common methods to be able to generate speed signals. In practice you will not find a shaft with every method applied to it.

Figure 1. Visualization of both the radial and axial measurements on a pole wheel.

Figure 1. Visualization of both the radial and axial measurements on a pole wheel.

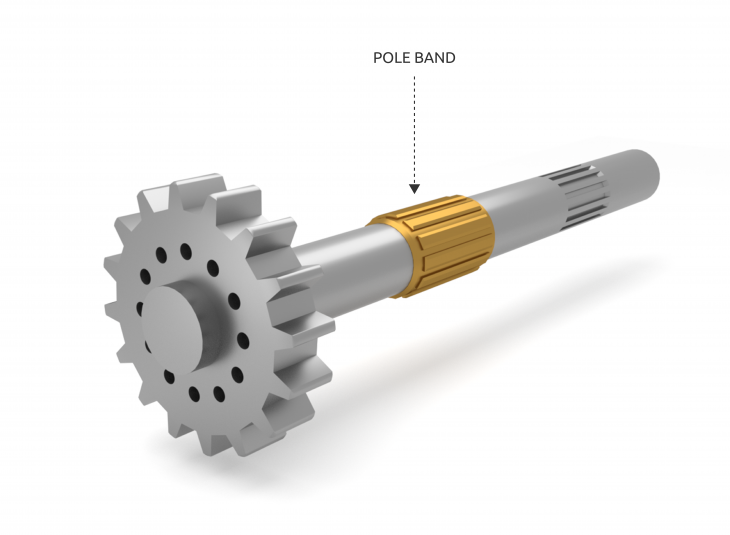

Pole band

When a pole wheel is not an option due to the compact design of the machine, a pole band can be used instead. A pole band is mounted around the shaft and its profile has protrusions, notches or slots to be able to generate pulses. These pulses are used to calculate the rotational speed.

![]()

Figure 2. Typical shape of the notches on a pole band.

Figure 3. Visualization of a pole band mounted on a shaft.

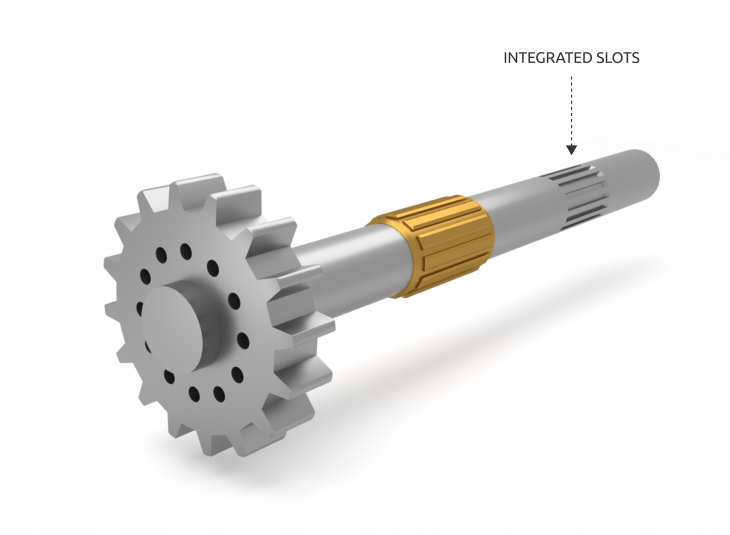

Integrated slots

The last commonly used method to generate speed signals are slots that are integrated in the shaft. This is only available when it is pre-engineered on the shaft by the OEM of the rotating machine. Generating pulses with integrated slots works the same way as with pole bands, using a similar profile.

Figure 4. This image shows integrated slots on a shaft.

Material

Sensors that convert a changing magnetic flux to a voltage or current output signal (e.g. VR, Hall-effect or eddy Current probes) typically require a ferro-magnetic (i.e. iron, nickel, cobalt) target object.