RheinEnergie operates critical rotating machinery that must perform continuously to ensure a reliable energy supply. The existing monitoring system, a VM600 Mk1 from Parker Meggitt with CMS software, had reached the end of its lifecycle. The challenge: implement a future-proof solution without modifying the existing Siemens server environment and with minimal downtime.

Challenge

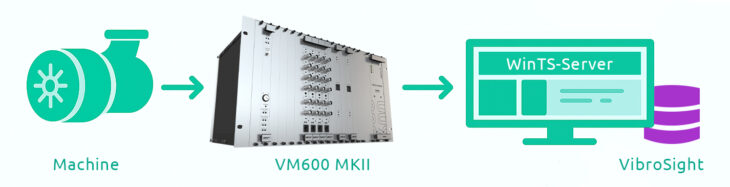

The system ran on a Siemens computer (WinTS server) that supports multiple process environments. This server had to remain in place due to existing connections and maintenance contracts. Replacing the monitoring system could not impact this infrastructure. In addition, the solution needed to meet the highest reliability standards and be prepared for future expansions.

Solution

A migration to the Vm600 Mk2 hardware combined with VibroSight software, the successor to CMS, was implemented. The new system was integrated on the same Siemens server without complex adjustments. This demonstrates that VibroSight is not only a powerful upgrade but also fully compatible with existing IT environments.

The migration was carried out while retaining the existing machine and server environment. VibroSight introduces advanced functionalities such as automatic data acquisition, alarm management, and optionally an integrated diagnostic rulebox. This enables operators to plan maintenance proactively and prevent unexpected downtime.

Integration Benefits

The transition to Mk2 and VibroSight delivered multiple advantages for RheinEnergie:

- Minimal downtime: One-to-one replacement of hardware and software kept downtime to an absolute minimum.

- Compatibility with existing infrastructure: The new system runs on the same Siemens server (WinTS), eliminating the need for additional hardware or complex IT changes.

- Reliability and future-proof design: Mk 2 and VibroSight provide a modern architecture that meets the latest industry standards and supports future expansions.

- Enhanced functionality: Advanced analysis such as rolling-element bearing monitoring and hydro air-gap control, plus flexible integration via OPC UA and Modbus.

- Efficient maintenance: Operators have powerful tools for predictive maintenance, reducing unexpected downtime and lowering maintenance costs.

Result

RheinEnergie now has a future-proof monitoring system that meets modern industry standards. The solution supports predictive maintenance, minimizes operational risks, and is ready for further digitalization. Thanks to Istec’s proven migration strategy, the transition from CMS to VibroSight was smooth, without disrupting operations and while retaining the Siemens server environment.

Old situation:

New situation:

Want to know how Istec can upgrade your outdated VM600 Mk1 system to Mk2 with VibroSight? Get in touch with our experts and discover the benefits of a proven migration strategy.