Istec VibSys®

Defining a new era of vibration monitoring

VibSys® is the next-generation vibration monitoring system and cloud gateway. It brings innovation to vibration monitoring through its compact design and advanced data capturing capabilities, making high-end analysis accessible to a wider range of applications. By bridging the gap between traditional infrastructures and modern IoT environments, it seamlessly integrates with existing analysis platforms.

Note: Availability expected in Q1 2026. The information on this page is therefore subject to change. Sign up to stay informed »

Benefits

Enhanced machine insights

VibSys continuously captures vibration data under real operating conditions, replacing fragmented snapshots with a complete and dynamic picture of machine behavior. This enables early anomaly detection, accurate diagnostics, and confident decision-making; empowering maintenance teams to shift from reactive to predictive maintenance strategies.

Any rotating machine

VibSys makes advanced vibration monitoring accessible to any rotating machine – from critical turbines to balance of plant equipment – due to its compact and scalable design. By minimizing cabling and safeguarding signal quality, it delivers high quality insights.

Open data infrastructure

VibSys features an open data infrastructure, allowing to integrate the vibration data with any preferred platform for analysis or data integration, like Istec analysis platform or any third party analysis tool, without the need for proprietary software.

“VibSys leverages cloud connectivity and an open infrastructure to deliver

unparalleled machine insights across any rotating machine.”

How does it work?

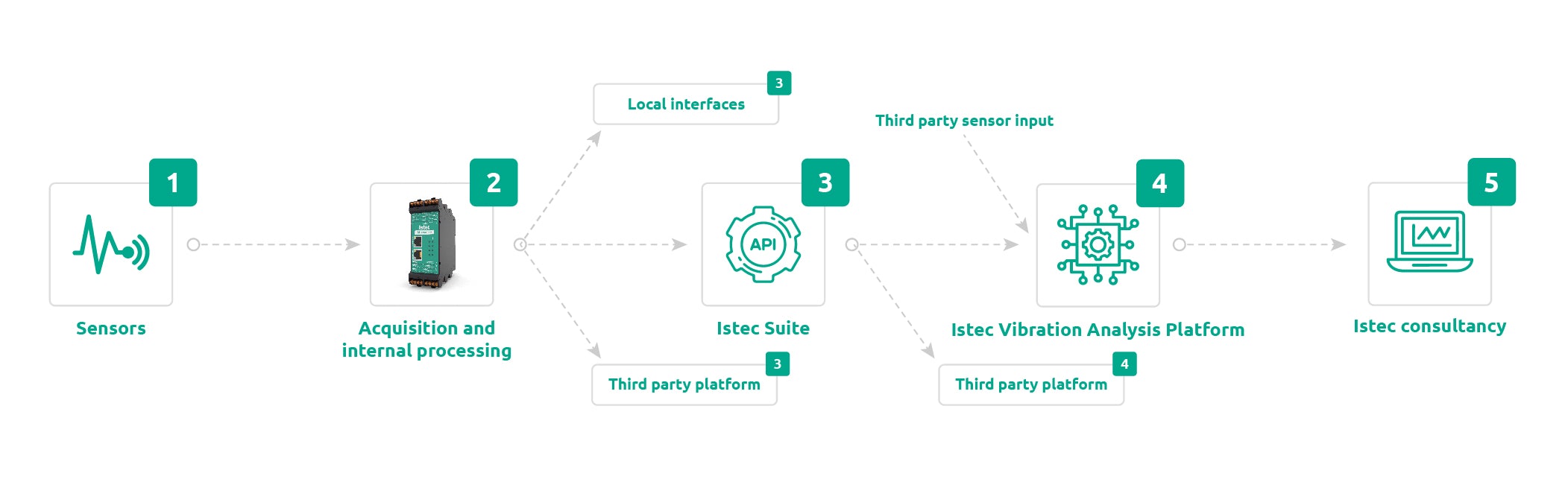

VibSys® functions as a modern gateway between vibration sensors and analysis environments, transforming raw signals into actionable intelligence. It acquires and preprocesses data at the source, delivering both raw time waveforms and extracted values through an open API without compromise in quality or availability.

Beyond vibration, VibSys® integrates speed and other critical machine parameters, creating a holistic view of asset behavior. Local outputs connect seamlessly to PLCs and DCSs, while secure data sharing unlocks advanced analytics on premises or in the cloud. This innovative approach makes vibration monitoring more accessible, scalable, and future proof for every industry.

Design

VibSys® features four independent channels, enabling time synchronised monitoring of multiple machine points for a more complete overview. Channel density can be scaled by interconnecting multiple VibSys® units. The compact DIN rail-mounted transmitter is designed for installation close to the asset, reducing cabling and preserving signal quality.

Typical applications include:

- ■Turbines

- ■Pumps and fans

- ■Gearboxes

- ■Wind turbines

- ■Paper machines

- ■Balance of plant equipment

Applications

Connectivity

Local and cloud access

VibSys® provides flexible access at every level. Local outputs connect directly to PLCs and DCSs for seamless control integration, while secure connectivity extends monitoring into advanced analysis environments and enterprise platforms. This combination ensures continuous insight, from machine-level data locally to complete fleet-wide visibility across sites.

API data interface

VibSys® makes processed data available through an open and secure API, allowing easy transfer to analysis software, data platforms, or control systems. This ensures interoperability across infrastructures, avoiding vendor lock-in while enabling flexible architectures. With full user control over data flow, organizations can build monitoring strategies that fit their digital ecosystem and scale with evolving demands.

AI Assisted Vibration Analysis Platform

The Istec Analysis Platform unlocks the full potential of VibSys® data by combining AI-driven first-line diagnostics, extensive trending, rule-based alerts, and advanced vibration analysis tools. As the number of monitored assets grows, the platform helps prioritize machines that require attention; maximizing maintenance efficiency and reducing downtime.

System

System features

- Four-channel device for vibration monitoring, scalable to higher channel densities by interconnecting multiple units

- High signal integrity for reliable measurements using industrial sensors

Connectivity options

- Ethernet (including Power over Ethernet)

- Modbus TCP

- CAN bus

- 4–20 mA process output for integration with control loops

Standards

- CE and UKCA certified

- EMC compliance: EN 61000 and EN 61326

- Electrical safety: EN 61010

- Data sharing: Secure transmission to analysis platforms, either on premises or in the cloud

Istec Category 1+ Vibration Training

As experts in vibration measurement and analysis, we provide an online training built on the ISO 18436-2 CAT1 standard. The course distills the essentials of vibration monitoring into practical video lessons, combining theory with real-world application.

The course captures the essence of vibration in a series of videos, and allows participants to earn the Istec Category 1+ certificate.

Downloads

There are no downloads available yet, as the product is still in active development.