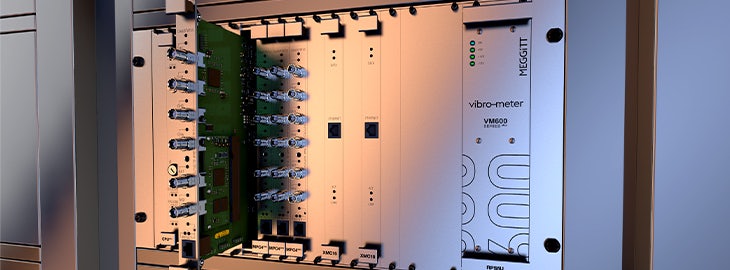

At its waste-to-energy plant in Weurt, near Nijmegen, ARN B.V. converts residual waste into sustainable electricity and heat. The facility operates almost continuously. Reliability is therefore vital, and downtime is costly. During a planned maintenance stop, ARN and Istec performed a vibration protection system replacement, upgrading the existing VM600 MK1 to the new VM600 MK2 vibration protection system.

The challenge: ageing protection systems

The previous VM600 MK1 systems, in service since between 2005 and 2012, became difficult to maintain due to card failures and hardware obsolescence. The FT3000* overspeed protection system had also reached the end of its life. To avoid multiple shutdowns, Istec proposed replacing both systems during one maintenance window.

ARN chose Istec because of its long-term partnership and proven expertise in turbine vibration protection and machinery safety. The VM600 MK2 offers the same functionality and user experience as the previous system. Its modern hardware and improved reliability made it ideal for ARN’s machinery protection system retrofit.

*Read about the replacement of the FT3000 in the following case study.

The solution: a smooth and precise replacement

Istec supplied and pre-configured the new system at its office in Lisse. The VM600 MK2 was delivered to ARN with clear wiring diagrams and configuration files. This allowed ARN’s team to complete the installation independently.

During preparation, a technical challenge arose: the relay card of the MK2 could, in this specific case, only be configured as normally de-energised, while the previous system used normally energised relays. Lars, Product Integration Engineer at Istec, tested the configuration and confirmed the limitation. He proposed relocating the relays to the input cards, preserving the original logic and functionality.

After installation, Istec conducted a full functional test to verify signal processing and alarm operation. “We found a small wiring issue during commissioning and fixed it immediately. It shows why the final verification step is so important,” explains Lars.

The result: reliability secured for years ahead

The new modern vibration protection system integrates smoothly into ARN’s infrastructure. It provides the same proven protection with modern hardware, improved diagnostics, and simplified configuration. According to Bas Willemssen, Maintenance Engineer at ARN, the collaboration was smooth and efficient.

ARN’s decision to perform the installation internally ensured control and strengthened its in-house expertise. By upgrading to the VM600 MK2 vibration protection system, ARN has secured long-term reliability and operational safety for its turbines.

The project stands as a successful vibration protection system replacement and machinery protection system retrofit, preparing the installation for many years of dependable service.