This article is part of the whitepaper: “monitoring mechanical behaviour of reciprocating machinery”. Request the whitepaper here »

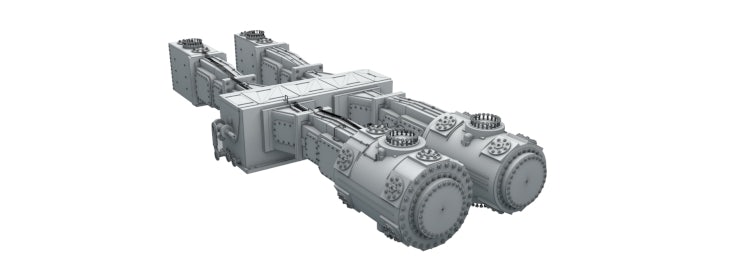

Reciprocating compressors are some of the most critical assets within a plant and is also one of the most maintenance-demanding types of machinery. Therefore, this type of machinery requires dedicated monitoring systems for several important parameters, to eliminate unscheduled maintenance and damage to machine parts. The most important mechanical indicators are discussed in the articles below.

Impact

Impact measurements are used as a reliable method to monitor reciprocating compressors. As the piston moves through the cylinder, impacts are produced that produce high amplitude peaks of very short duration. As these signals can hardly be measured by vibration sensors, impact sensors are used instead.

Read the full article about impact monitoring on reciprocating compressors here »

Temperature

There are various components in reciprocating compressors that are influenced by temperature, including suction and discharge valves, and bearings. The temperature of these components must therefore be monitored to prevent damage or a decrease in compressor efficiency. There are several temperature sensors to monitor reciprocating compressors.

Read the full article about temperature monitoring on reciprocating compressors here »

Vibration

Vibration measurements on piston compressors can be difficult due to the natural behaviour of reciprocating compressors. However, there are some important machine parts that must be monitored for changes in vibration behaviour.

Read the full article about vibration monitoring on reciprocating compressors here »

Rod displacement

Rider bands are important parts that support the piston as it moves through the cylinder and ensure that there is no metal-to-metal contact between the piston and the cylinder wall. These rider bands wear out over time, which results in the lowering of the piston and the piston rod. To ensure that no damage is caused to the piston and the cylinder wall, rider band wear must be monitored. To do so, the vertical displacement of the piston rod is monitored.

Read the full article about monitoring rider band wear here »