The API Standard 670 is an industry standard and describes the minimum requirements for a machine protection system (MPS). This includes, measuring radial shaft vibration, casing vibration, axial shaft position, shaft rotational speed, piston rod drop, phase reference, overspeed and critical machine temperatures.

The standard includes requirements related to hardware (sensors and systems), installation, documentation and testing. In this article, we focus solely on the part that describes overspeed and limit ourselves to this standard. The main elements are described.

The definition of overspeed

Overspeed occurs when the rotational speed of a rotating machine, such as a steam or gas turbine, exceeds its design limits. The consequences of an overspeed event vary per type of machine and per model. The time that the overspeed event lasts and the degree of overspeed relative to the design limit are also decisive for the consequences.

Even though manufacturers usually give the machinery a certain safety margin in the design with regard to exceeding the maximum rotation speed, an overspeed event can lead to rapid and impactful damage development. To prevent this, it is important to equip the machine with an overspeed monitoring system.

This article continues below

Want to learn more about overspeed? Request a free copy of our book Speed »

(due to the limited number of copies, we recommend you to pre-order the book now!)

Electronic overspeed detection

In the past, machines were monitored by mechanical overspeed protection, but nowadays electronic overspeed protection is the standard. Therefore, the API 670 only describes the requirements of electronic detection systems and defines them as follows:

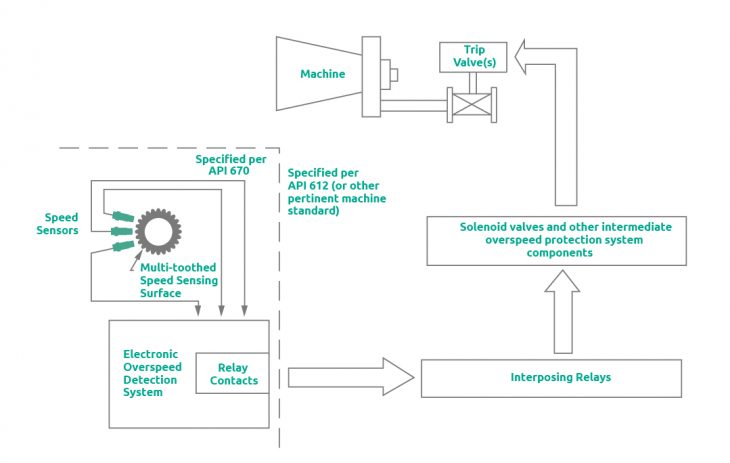

An electronic overspeed detection system consists of speed sensors, power supplies, output relays, signal processing, and alarm/shutdown/integrity logic. Its function is to continuously measure shaft rotational speed and activate its output relays when an overspeed condition is detected.

Separate hardware and logic

The API 670 describes that an electronic overspeed detection system must be exclusively dedicated to overspeed detection. The system must be isolated from other monitoring and protection systems and is not allowed to share components. This ensures that the functioning of the system is verifiable and not dependent on other systems.

Response time

An electronic overspeed detection system, for those machines to which the API standard 670 applies, must consist of three independent measuring circuits. To maximize the safety and availability of the machine, a two-out-of-three voting (2oo3) is used to activate the trip function. In other words, if at least two of the three sensors detect overspeed, the trip function will be activated.

Voting is related to the architecture of a trip system (1oo2, 2oo2, 2oo3, and so on). It can be defined as the minimum number of “paths” that should function out of the total number of paths available within the architecture. For example, with a 1oo2 architecture at least one path should function, whereas with a 2oo4 architecture at least two paths should function.

It goes without saying that the response time during an overspeed event is very important. The API 670 describes that the system may take up to 40 milliseconds to detect overspeed and have the relay outputs switch. It should be noted that 40 milliseconds is not always fast enough to prevent the rotor from reaching a speed above its design specifications due to the ramp-up.

The following actions must take place within these 40 milliseconds:

- All three measuring circuits (channels) measure the rotation speed.

- The measured values are independently compared to the set the trip value.

- The voting structure determines how many measurement circuits have determined an overspeed event.

- When at least two of the sensors have detected overspeed, the output relay should switch.

In the diagram below, these steps are shown schematically:

Schematic representation of an electronic overspeed detection system; three sensors pointed at the measuring surface, connected to the detection system where voting takes place with a relay as output.

Source: API Standard 670

SpeedSys

Our philosophy is met by SpeedSys; a SIL-rated overspeed detection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint and low-impact installation enables advanced protection to a wide range of applications. SpeedSys is available in two versions. SpeedSys 200; for less demanding SIL 2 applications and SpeedSys 300 for demanding and critical SIL 3 applications.

The speed product brochure provides a complete overview of our tachometers, overspeed detection systems, and speed sensors.