Understanding the behavior of rotating machinery is essential to ensuring the reliability and longevity of your assets. In this in-depth article, Istec explores how orbit analysis serves as a powerful diagnostic tool in vibration monitoring, enabling early detection of faults such as imbalance, oil whirl, rubs, and shaft cracks in turbine systems. Discover how this technique contributes to predictive maintenance strategies and helps prevent catastrophic failures.

Orbit analysis as a diagnostic tool for turbine maintenance

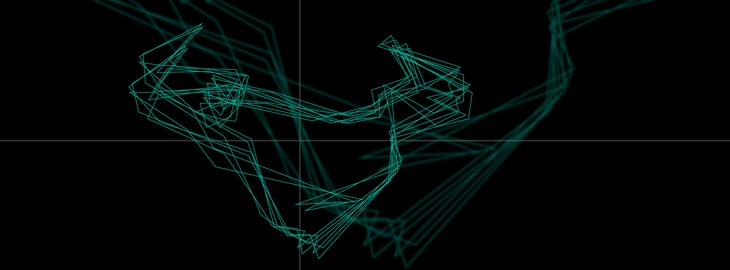

This article provides a comprehensive overview of how orbit analysis can identify various mechanical issues by examining the motion of a turbine shaft within journal bearings. Using dual proximity sensors, specialists can detect anomalies such as excessive preload, oil whip or loose components. These issues might otherwise remain hidden. The visual patterns of the shaft’s movement (orbits) reveal emerging problems before they escalate, offering critical insights that support timely maintenance decisions and improve machine uptime.