The production lines in the pulp and paper industry consist of various sections with many rotating machines and rolling elements. Each section is essential for the process, so for maximum productivity, it is important to prevent unplanned and unnecessary downtime. In this article, we will explain which environmental factors need to be considered when choosing the right vibration sensors and what the correct procedure is for handling the cabling.

Paper production is a continuous process, which means that downtime of a machine results in high costs. The cost of bearing damage can quickly add up because depending on the configuration, there can be between 200 to 400 bearings in the machine.

Sensor choice

The process of making paper can be divided into four sections: the sheet forming section, the press section, the drying section, and the calender section. For choosing the right sensors, it is important to inventory which machines we can encounter in a paper mill and what vibration characteristics can be expected. It is also important to consider the various environmental factors that occur in some parts of a paper mill such as: high temperatures, high humidity, and the presence of chemicals.

For each section, we describe the machines and the environmental factors that need to be considered in the sensor choice. In all sections, a low frequency can be assumed because the RPM of all rolling elements is low to very low.

Sheet forming section

Environmental factors: steam, water spray, high humidity, chemicals (chlorine)

Machines: feed pumps, pulverizers, mixers, suction rolls

Wood pulp tends to clump together, making it necessary to mix the wood pulp with a lot of water so that the slurry can be evenly distributed to form a sheet. Therefore, this section involves both a high level of humidity and in the process. Suction rolls press the moisture out of the paper sheet, reducing the moisture content of the final product from 99.5% to 75%.

Istec offers various vibration sensors (accelerometers) specifically suitable for this section: Wilcoxon 786A, 787A, 797L and 799LF. We also offer various cables with connectors conforming to IP68 and IP67.

Press section

Environmental factors: water, corrosive chemicals

After the paper is formed, the moisture must be pressed out again, which is done by means of press rolls and felt rolls. Since the rolls, like in the forming section, rotate slowly and there is still a lot of moisture in the process, we recommend similar sensors and cabling as in the forming section. In the press section, the moisture content of the final product is reduced to about 60%.

We recommend the following vibration sensors (accelerometers): Wilcoxon 786A, 787A, 797L and 799LF. We also offer various connectors with cables that are water-resistant: Wilcoxon R6QI (IP68) or R6W (IP67).

Drying section

Environmental factors: high temperatures, steam, static electricity (ESD)

Machines: press rolls

In the drying section, the steam-heated press rolls ensure that more water is removed from the product, and the moisture content is reduced to about 6%. The temperatures in this section range around 110 ºC and 140 ºC. It is important to realize that grease-lubric

ated bearings become hotter than oil-lubricated bearings where the oil circulates thus building up less heat. Also, it is an important fact that the speed of the rollers here is much higher, making it no longer necessary to use low-frequency accelerometers.

In this section, we recommend the following vibration sensors (accelerometers): Wilcoxon 786A, 787A, 793-6 and 797-6 in combination with (cables) connectors R6QI (IP68) or R6W (IP67).

Calender section

Environmental factors: high temperatures, steam

Machines: calender

The final step in the process is calendering. Calendering is the forming of a thermoplastic mass between two or more rolls into a film by means of a calender. A calender is a series of rolls, which are used to create a smooth and glossy surface of the paper.

The sensor choice in this section depends on the configuration of the machine. Contact us for further advice on the sensor choice for this machine.

Cabling

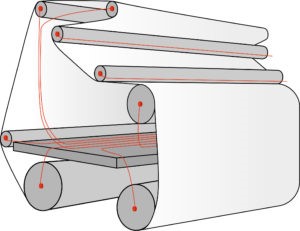

In addition to the right sensor choice, it is important that the cabling is laid and mounted correctly. When hiding the cabling, it is important to follow the following principles:

- Never let the cabling cross the production process.

- Lead the cables of the sensors that are mounted on the front side through the inside of the production process. This simplifies the removal of unfinished paper if, for any reason, the production process is halted.

- Lead the cables of the sensors that are mounted on the inside of the production process through the inside, and lead the cables of the sensors that are mounted on the outside of the production process on the outside.

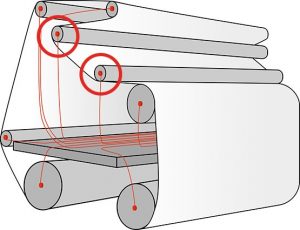

Figure 1 – Incorrect cabling; two cables from sensors mounted on rollers at the top of the process cross the production process. However, these should be led at the top of the process.

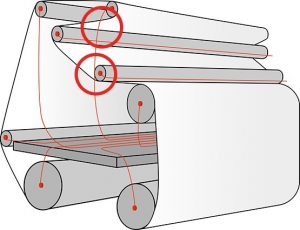

Figure 2 – Incorrect cabling; although the cable of the innermost roller on the top right is led on the inside of the production process, it still crosses the production process.

Figure 3 – Correct cabling. There are no cables that cross the production process.

Vibration analysis

Vibrations in slowly rotating machines are difficult to analyze because the vibrations can come from various sources. The following factors affect the performance of the machine and sensitivity to vibrations:

- The width and diameter of the roll

- The type of bearing, as CARB bearings can change running track causing some damages to only be seen under certain machine conditions

- The thickness, stiffness, and typeof paper material

- The machine width

- The structure and stiffness of the machine

- The rotational speed of the rolls

- The condition of the bearings, drive shafts, and couplings

- The machine foundation

- Other machines in the environment