Understanding the Role of Vibrations in Rotating Equipment Monitoring

Vibration measurement on bearings offers a reliable way to monitor the condition of rotating machines. These include steam turbines, gas turbines, compressors, fans, pumps, mixers, rollers, gearboxes and motors. Even reciprocating compressors benefit from vibration monitoring. Technicians measure vibrations in three directions: axial, horizontal and vertical. This approach helps them pinpoint the vibration’s direction and frequency. Experts then analyze this data using spectrum and orbit techniques to identify issues early and provide targeted maintenance advice.

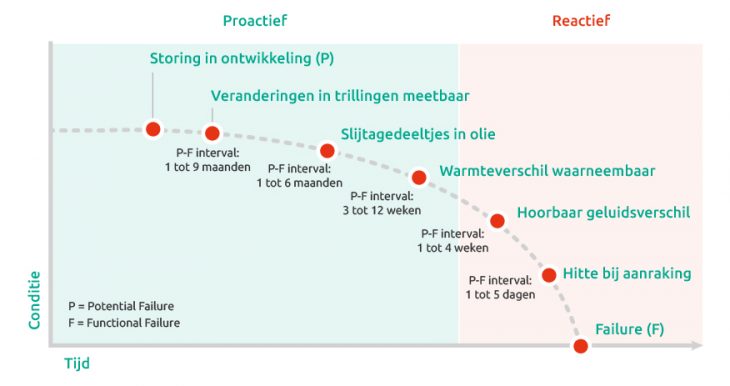

P-F interval

The graph above shows the P-F interval, which tracks the time between the first signs of failure and total functional breakdown. Each stage in this curve highlights which diagnostic methods are most effective and how much time is left to intervene before significant damage occurs.

How Vibration Measurement on Bearings Prevents Failure

Vibration is often the earliest detectable symptom of developing mechanical problems. Detecting these changes in time gives engineers the opportunity to act before any damage escalates. Other early warning tools like oil analysis and infrared thermography are also valuable, but they tend to identify faults at a more advanced stage. By using vibration measurement on bearings as a primary tool, maintenance teams gain a significant head start in preventing failure.

Proactive and Reactive Maintenance Strategies

Changes in vibration levels allow for proactive maintenance, giving teams time to address root causes before they become serious. Oil analysis and thermography can complement this strategy. However, when no proactive measures are taken, reactive action is the only option left. At that point, symptoms like unusual machine noise, surface heat or even smoke may appear, indicating that urgent intervention is required to limit damage.

The Role of a Certified Vibration Specialist

Proper analysis of vibration data requires skilled professionals. Istec employs vibration specialists who are certified under ISO 18436-2 at both level 3 and level 4, with level 4 being the highest internationally recognized standard in vibration diagnostics in rotating machinery. These specialists use advanced tools and deep technical insight to interpret vibration patterns, detect mechanical issues early and support maintenance decisions that improve machine reliability.

Main Causes of Vibration in Rotating Machinery

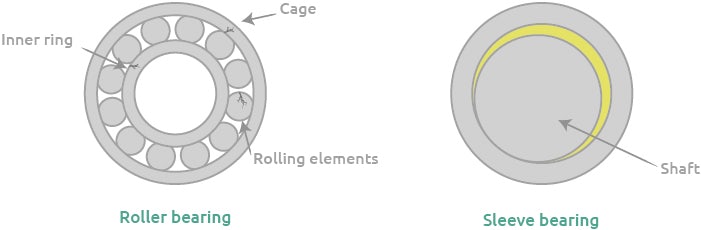

Several mechanical issues can lead to excessive vibration. One of the most common causes is bearing damage. Poor lubrication, contamination, corrosion, overload or excessive heat can degrade the rings, cage or rolling elements of the bearing. For detailed insights, download the whitepaper: [Damage to Rolling Bearings (PDF)].

Another frequent cause is misalignment, which occurs when the shafts of two coupled machines do not align properly. This results in uneven load distribution and increased mechanical stress. Imbalance is also a major contributor, where a shifted center of gravity in rotating components leads to unbalanced force, causing excessive wear on the bearings during each rotation.

Also read our knowledge article: The 4 most common causes of vibrations in rotating machines »