Piëzoelectric accelerometers (CA-serie)

For applications that do not require the temperature capabilities of a CA sensor, this series offers a more cost-effective and easier-to-install solution.

Designed for the long-term measurement and monitoring of absolute vibrations in heavy-duty environments, such as gas or steam turbines, compressors, pumps, and fans.

Main features:

- Available in standard versions and in Ex versions certified for use in hazardous areas.

- Signal conditioning: confirmed or integrated electronics.

- Note: No external signal processor, so no connectors close to the monitored machine and easier to install. High-temperature environments and low-frequency applications.

Models

Meggitt Vibro-meter – CE134

- Designed for the long-term measurement of vibrations in heavy-duty environments, such as gas turbines and compressors.

- Wide temperature range: −55 to 350 °C

- High-frequency response: up to 10000 Hz

- Current output (5 µA/g) for signal transmission over long distances: up to 1000 m

- Certified for use in potentially explosive atmospheres

Meggitt Vibro-meter – CE281

- Designed for the long-term measurement of vibrations in heavy-duty environments, such as gearboxes, compressors, pumps, and fans

- Wide temperature range: −55 to 260 °C

- High-frequency response: up to 7000 Hz

- Current output (10 µA/g) for signal transmission over long distances: up to 1000 m

- Certified for use in potentially explosive atmospheres

Meggitt Vibro-meter – CE311

- Designed for the long-term measurement of vibrations in heavy-duty environments, such as heavy gas turbines and steam turbines.

- High-frequency response: up to 8000 Hz.

- High sensitivity: 50 µA/g.

- Current output (50 µA/g) for signal transmission over long distances: up to 1000 m.

- Certified for use in potentially explosive atmospheres.

Meggitt Vibro-meter – CE620

- Designed for general vibration measurement, typically in installations such as compressors, gearboxes, motors, pumps, and fans

- Industry-standard IEPE (integrated electronics piezoelectric) vibration sensor

- Dynamic voltage output signal (100 or 500 mV/g) suitable for spectrum analysis

- Usually connected to a machine monitoring system for protection and/or condition monitoring applications

- IP68 protection rating

Meggitt Vibro-meter – CE630

- Designed for general vibration measurement, typically in machines for general use such as compressors, gearboxes, motors, pumps, and fans

- Industry-standard IEPE (integrated electronics piezoelectric) vibration sensor

- Dynamic voltage output signal (100 or 500 mV/g) suitable for spectrum analysis

- Usually connected to a machine monitoring system for protection and/or condition monitoring applications

- IP68 protection rating, side connector

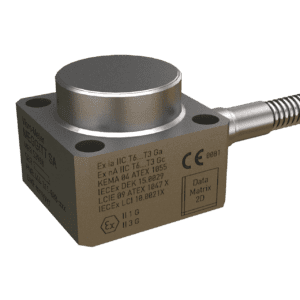

Meggitt Vibro-meter – CE687

- Designed for general vibration measurement, typically in installations such as compressors, gearboxes, motors, pumps, and fans

- Industry-standard 4 to 20 mA loop-powered vibration sensor (vibration transmitter)

- Quasi-static output signal (4 to 20 mA proportional to 0 to 10 or 0 to 20 g) indicating “general

In short:

Downloads

Want to receive multiple files to your email? Click on the map-icon to add the download to your folder, and send them by clicking on the bottom right.