The Envea MaxxFlow is an inline mass flow meter specially developed for measuring the mass flow of dry bulk goods without influencing the flow. This article discusses some applications of the MaxxFlow.

Learn more about the Envea MaxxFlow »

The open construction and compact form, combined with a very high throughput capacity, make the MaxxFlow usable in situations where previously only complex mechanical systems such as weigh hoppers or impact flow meters were applicable. The MaxxFlow can be easily calibrated and sends measurement data directly to the control system.

The advantages of the MaxxFlow over an impact flow meter »

The electromagnetic flow meter works contactlessly and is completely dust-proof and erosion-free due to the ceramic interior of the pipe. As a result, the MaxxFlow is virtually maintenance-free and has a long lifespan.

The MaxxFlow can be installed in various ways:

- Vertically:

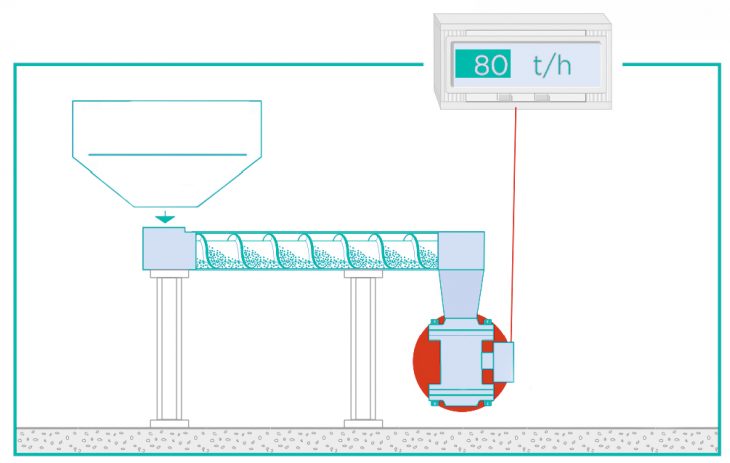

Image 1. Example of the installation of the MaxxFlow after a screw conveyor, with a flow of 80 t/h.

Image 1. Example of the installation of the MaxxFlow after a screw conveyor, with a flow of 80 t/h.

- Inclined:

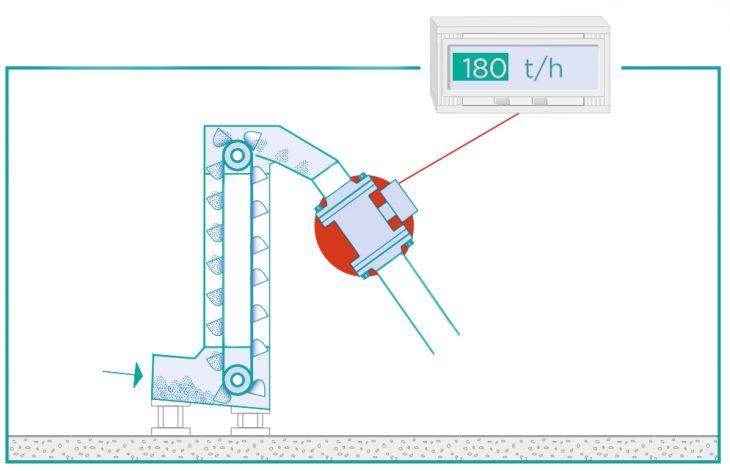

Image 2. Example of the installation of a MaxxFlow after an elevator, with a flow of 180 t/h.

Image 2. Example of the installation of a MaxxFlow after an elevator, with a flow of 180 t/h.

Application: Mass Flow

A cement manufacturer mixes three materials in a screw mixer: cement, ash, and filter powder. To ensure accurate dosing of the materials, the quantities at the discharge of the silos must be measured. These measurements are used as a reference parameter for the dosing of additives. For this application, each silo needs its own system to measure material discharge. The dosing of the material discharge is controlled via a slide valve.

Solution

The MaxxFlow HTC is used to measure the material flow from the silos. This application involved a material flow of 70 t/h of cement, 30 t/h of ash, and 20 t/h of filter powder from three different silos.

Image 3. Installation of MaxxFlow at the discharge of one of the silos.

Advantages for the customer:

- Precise control of material flow

- Simple and quick calibration

- No installation in the flow

- Robust and a long lifespan

Do you want to know if the MaxxFlow fits your specific application? Contact one of our application consultants.