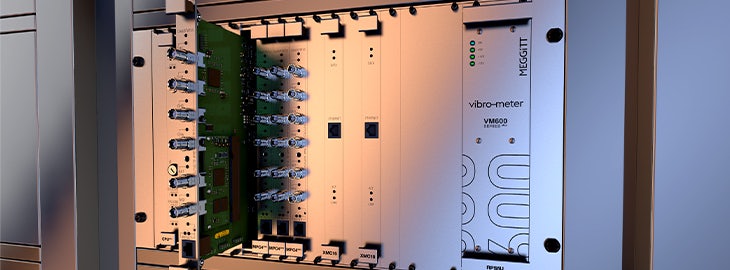

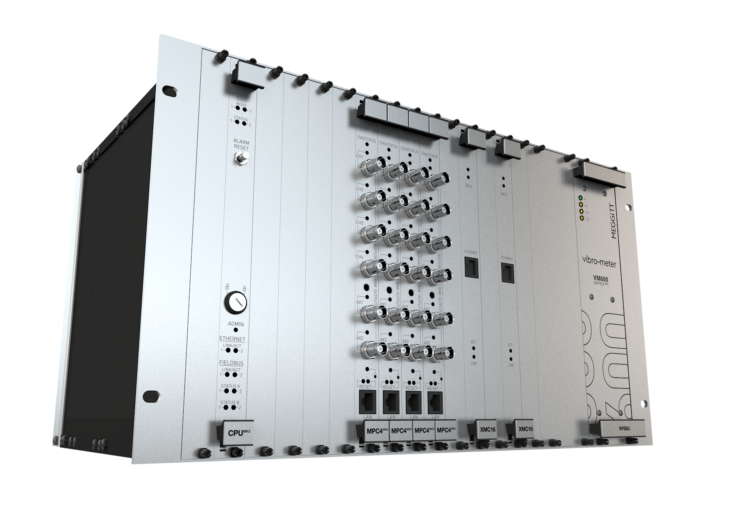

Introducing the Vibro-meter VM600Mk2: Machine protection and condition monitoring system

Meggitt Vibro-meter recently launched the VM600Mk2, the second generation of their VM600 machinery protection system. This new system is a significant upgrade from its predecessor, which was introduced more than 20 years ago. In this article, we will highlight the 6 key differences between the VM600 and the VM600Mk2.

Go to the VM600Mk2 product page »

Integrated protection & monitoring

One major difference is the integration of protection and condition monitoring through the new MPC4Mk2 module and the I/O module, which provides integrated protection and condition monitoring without compromising cybersecurity. This eliminates the need for an XMV16 module to facilitate condition monitoring functions. The integration offers several benefits:

- It eliminates the data dissimilarity issues that are inherent in two separate signal processing paths and alarm processing paths. Alarms and data are perfectly synchronized between the condition monitoring and protection environment.

- It speeds up the configuration process because the configuration elements that are common to both the protection and condition monitoring systems no longer need to be duplicated.

- The MPC4 protection modules are not necessary to use a VM600 rack purely for condition monitoring. The XMV16 module can then be used to set up an effective condition monitoring system with 16 channels per rack slot. This can be an addition to existing third-party protection systems for customers who want comprehensive analysis options and integrate VibroSight software.

SIL 2 by design

Another significant improvement is the SIL 2 certification that the VM600Mk2 was designed for. The first generation VM600 achieved SIL 2 certification after years of usage data, but the VM600Mk2’s MPC4Mk2 and RLC16Mk2 were designed for SIL 2 certification. Monitoring modules such as the XMC16 and XMV16 do not require SIL certification.

Learn how SIL by design is different from proven-in-use »

Improved relay capabilities

The VM600Mk2 also features improved relay capabilities.

- The relays in the RLC16Mk2 and MPC4Mk2 modules are now epoxy-sealed for better environmental protection.

- The MPC4Mk2 modules now have 5 relays instead of 4, with the fifth allocated for module fault indication.

- Wiring contacts for both Normally Open (NO) and Normally Closed (NC) positions are now available from each SPDT relay

- Normally energized and normally de-energized operation of relays can now be configured from software instead of hardware jumpers.

Improved cybersecurity

The cybersecurity of the VM600Mk2 has significantly improved. The new MPC4Mk2 card uses a different software environment for making changes to protection functions than to condition monitoring functions, ensuring that condition monitoring and safety functions are strictly separated, even though the new MPC4 card features both protection and monitoring functions. A failure occurring only in the condition monitoring portions of the MPC4Mk2 card, cannot impact its protective functions. The new design allows the protective system to share measurements and alarm statuses with the condition monitoring environment, without compromising safety. Physical security measures, such as a physical lock on the MPC4Mk2 module and password-controlled access, provide an additional layer of security.

Improved configuration software

The VM600Mk2 also comes with entirely new configuration software that significantly cuts the configuration time. The system, its modules, and rack slot distribution are depicted graphically to make it more user-friendly.

Simplicity and versatility of the VM600Mk2

The VM600Mk2 retains and extends the simplicity of the first-generation platform, eliminating the need for separate XMV16 modules when combined protection and condition monitoring functionality is required. The MPC4Mk2 contains five relays, which means most users will not need to use a separate relay module (RLC16Mk2) for an adequate number of relays. The system consists of only three module types, resulting in a simple and efficient system.

Your vibration expert

By combining Vibro-meter’s cutting-edge technology with our proficiency in condition monitoring services, we offer our customers advanced vibration analysis solutions. Our dedication to excellence ensures that we not only provide high-quality data but also offer insightful analysis to help our clients make informed decisions about their machinery. Our team of certified vibration analysts is highly skilled and experienced in analysing vibration data to detect potential machinery problems at an early stage. We collaborate closely with our customers to develop solutions that meet their specific needs. Our ultimate objective is to offer our clients a solution that includes all aspects of vibration analysis, from data collection to expert analysis and support.