What is electrical loop take-over and how does it help me with my DCS migration?

Electrical loop take-over is the unique process that Istec implemented in the hot cutover tool to make hot cutover DCS migrations safer and easier.

Electrical loop take-over is the unique process that Istec implemented in the hot cutover tool to make hot cutover DCS migrations safer and easier.

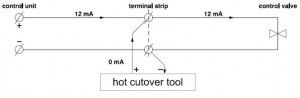

When connected to a control loop, the hot cutover tool can take over the loop control from the DCS, allowing the user to disconnect and replace the DCS during active process conditions. The tool maintains the loop value and absorbs any offset generated by e.g. connecting the new DCS. Check the application flow for more information.

How do I connect the hot cutover tool to the control loop?

The IST-203 is connected in parallel to the DCS. The connection is usually made in the marshalling cabinet and depends on the connection possibilities in the cabinet. Check the wiring diagram or the product manual for more information.

Can the hot cutover tool be used on all DCS systems, even very old systems?

Yes it can. To facilitate the hot cutover DCS migration, the tool is connected to the loop in parallel with the DCS. It works with the 4-20 mA loop, independend of the DCS itself.

Can I use the hot cutover tool for DCS migrations in hazardous areas?

Using a barrier can make life a little easier in some situations. Integrating it in the unit would however limit its applications, due to the increased loop resistance. It is also not allowed to mix ATEX and pre-ATEX components in one loop. An external barrier can be used, however this requires further on-site risk analysis, e.g. which model suits the area, the loop resistance, the old/ new certifications, how is the connection of the barrier to the IS earth guaranteed and so on. This should be determined on site.

In addition, the process of a loop take over itself is regarded as a high risk and should be performed under a hot work permit. Before a loop take over starts a risk analysis needs to be performed to evaluate the possible consequences. This must include the impact of working in a hazard area. A single component of a complex process is briefly taken over during a DCS migration. Typical duration of a loop take over is 10-20 minutes.

A survey under the users of previous versions of the hot cutover tool showed that, when required, gas monitors during a loop take over are preferred over an internal or external barrier.

How long does it take to perform a DCS migration?

With the hot cutover tool, an actual loop migration takes about 10 minutes. Field experience showed us that one tool can be used to migrate about 40 loops per day, dependent of the quality of the pre-studies. The IST-203 hot cutover tool facilitates parallel migrations as well, to speed up the process even further.

Is it possible to verify the output direction of the new DCS with the tool?

Yes, it is. When the IST-203 is in take-over mode, the current contribution is displayed in the screen. When the new DCS is connected, the output values can be adjusted and the direction of the value change can be read from the screen.

Can the IST-203 be connected to the mains power supply to lengthen usage time?

No. Due to the capacitive coupling of the charger Istec cannot control grounding errors which may lead to control failure. Therefore, the IST-203 prevents charging during take-over. The tool comes with clear battery indicators, take-over prevention in low battery situations and a build-in backup battery for emergencies.

Can I control my valve during take-over?

Yes. The IST-203 comes with an offset control function. During take-over, the loop values can be adjusted if necessary to manually control the valve.

What do I do with input signals from e.g. transmitters?

The tool takes over the DCS output signal to maintain the valve position, as it reproduces the DCS output signal. Input signals are regarded as non-critical, as they only have an indirect influence on the production process and can be migrated without take-over.

Click here to contact our specialists for more information.

Related pages: IST-203 Hot Cutover Tool , Application Flow