Periodic Condition Monitoring can be used to determine the change in vibration behavior of the machines. By having a fixed interval, vibration measurements can construct a trend analysis. The advantage of periodic Condition Monitoring is the regular checks executed on the devices. This offers a lot of security.

Periodic Condition Monitoring creates a database containing information about the condition of the machine. The correct establishment of a database with the correct measurement settings is essential for the process and requires specialist knowledge and experience. When a change is visible in the trend, it is reported and explained in frequent reports. All other deviations are also analyzed.

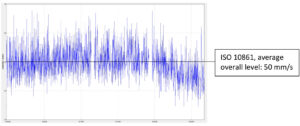

The trend value is an average value over a preset frequency range. This is an indication for any change in the machine behavior. The trend analysis can tell what the cause of this change is. For example, predictive measures may be recommended. These differ from a lubrication advice to checking the alignment or replacing machine parts such as bearings.

Based on the type of installation, the application and the risk, a measuring program is set up. The measurement program consists of the systems that are measured, the number of measurements per year, the used equipment and implementation. The specialists of Istec provide appropriate support, from guidance in setting up a measuring program to full implementation and reporting.