“20 billion is lost each year due to unplanned downtime” (Automation.com, 2016).

An effective way of predictive maintenance has been an important topic within the industry for years. Often, it was difficult for companies to derive economic benefits from it. However, with today’s technologies, it is increasingly easier to gain economic advantages from predictive maintenance. First, it is important to realize that unplanned downtime causes incredibly high costs. The production process is unexpectedly halted, no production can take place, unplanned repair costs are much higher than planned maintenance, and often sudden high investments must be made in new installations or machine parts.

Moreover, many companies have a delivery obligation. When the production process suddenly stops, a company cannot meet its delivery obligations and may have to buy the respective product from a competitor to fulfill its obligations, incurring enormously high costs.

Predictive maintenance is the solution and is also known as condition based maintenance. Through Condition Monitoring or machine monitoring, the lifespan and future maintenance of machines can be determined. This ensures that small interventions do not escalate into major maintenance requiring a long production stop. According to a study by the World Economic Forum and Accenture, some major benefits of predictive maintenance are:

Predictive maintenance is the solution and is also known as condition based maintenance. Through Condition Monitoring or machine monitoring, the lifespan and future maintenance of machines can be determined. This ensures that small interventions do not escalate into major maintenance requiring a long production stop. According to a study by the World Economic Forum and Accenture, some major benefits of predictive maintenance are:

- 12% less spending on planned maintenance

- 30% less repair costs

- 70% less unplanned downtime

These figures and the increasingly efficient predictive maintenance ensure that more and more companies are paying close attention to predictive maintenance. Condition Based Maintenance has a significant advantage over preventive maintenance. While preventive maintenance applies maintenance and replacement to machines in a fixed cycle, predictive maintenance takes a better look at the current state of the machine and the trend in which the machine is developing. In preventive maintenance, it often happens that machines or machine parts are replaced without actually being necessary. This incurs unnecessary and high costs. Predictive maintenance ensures that machines are optimally utilized throughout their lifespan, saving a lot of costs.

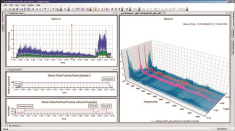

Istec Condition Monitoring

A department within Istec International specializes in Condition Monitoring, which enables predictive maintenance. Our specialists carry out spectrum and trend analyses to determine the state of installations and based on these analyses, they provide maintenance advice. They also implement monitoring systems and build complete instrumentation cabinets. Our specialists offer many possibilities regarding Condition Monitoring, such as: periodic, online, and remote Condition Monitoring. Read more about our services for predictive maintenance here »